Valve Safety in High-Pressure / High-Temperature Applications

Valve safety in high-pressure and high-temperature applications is essential for steam systems and chemical plants. This guide explains materials, thermal stress, sealing, maintenance, and safety standards needed to prevent catastrophic valve failure.

How to Choose the Right Repair Kit for Your Valve Model

How to choose the correct valve repair kit, avoid common ordering mistakes, and ensure OEM compatibility for reliable industrial valve maintenance.

Step-by-Step Valve Inspection Checklist for Maintenance Teams

A practical step-by-step valve inspection checklist for maintenance teams covering what to inspect, how often to inspect, and which measurements to record to prevent failure and improve reliability.

Understanding Valve Trim & When It Should Be Replaced

A practical guide explaining what valve trim is, how it wears, the materials used, and the warning signs that indicate replacement is needed to maintain safe and efficient valve operation.

How Valve Actuators Work: Pneumatic vs Electric vs Hydraulic

A clear guide explaining how pneumatic, electric, and hydraulic valve actuators work, including their applications, advantages, and limitations for industrial automation.

Valve Storage & Preserving Equipment Between Projects

Best practices for valve storage and actuator preservation. Learn how to prevent seal damage, corrosion, and failure while equipment is stored between projects.

What Is Control Valve Calibration?

Control valve calibration ensures valves respond accurately to control signals, protecting process stability, safety, and efficiency. This guide explains why calibration matters, the tools involved, and how technicians perform it in real-world applications.

Why Choosing the Correct Valve Repair Kit Matters

Choosing the right valve repair kit is essential for safety, performance, and long-term reliability. This guide explains how to identify your valve model, match OEM components, avoid common ordering mistakes, and ensure compatibility before installation.

Common Causes of Valve Failure & How to Prevent Them

Industrial valve failure can lead to downtime, safety risks, and expensive repairs. This guide explains the most common causes of valve failure — including wear, corrosion, thermal stress, poor installation, and neglected maintenance — and how preventative strategies can extend equipment life.

What Is Valve Refurbishment?

A detailed guide explaining what valve refurbishment is, why it matters, and the full workflow from disassembly and cleaning to machining, reseating, and pressure testing.

What Is Valve Pressure Testing?

A complete guide to valve pressure testing covering hydrostatic and pneumatic methods, procedures, safety rules, and how to interpret results to ensure safe industrial valve operation.

Valve Repairs Are Just the Start – Here's How Our Group Supports Every Part of the System

ValvesRepair.com is your go-to for actuator and valve repair kits — but our group goes much further. In this blog, we explore how the wider Actuation Valve Group supports full systems, from bronze valves and ball valves to automation, feedback, and fabrication.

How Do You Know When to Repair Your Valves?

Valves are essential to safe and efficient operations, but how do you know when to repair your valves? From leaks and reduced performance to unusual noises and corrosion, there are clear signs that it’s time for maintenance. Discover when repair is the right choice and how timely servicing can save money, extend valve life, and keep your system running reliably.

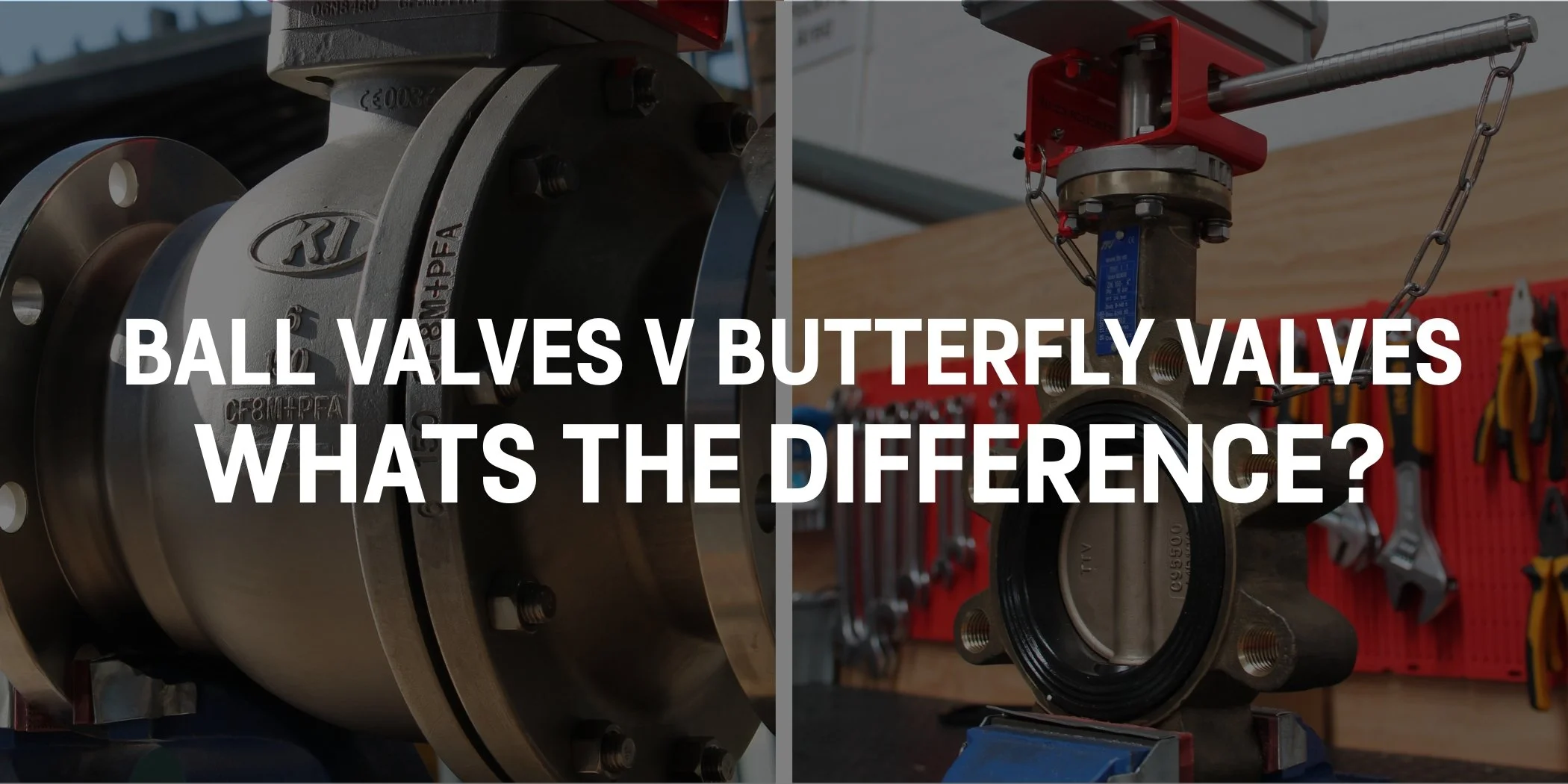

Ball Valves v Butterfly Valves: What’s the Difference?

Ball valves and butterfly valves are two of the most common flow control options, but they serve very different purposes. If you’ve ever asked, Ball Valves v Butterfly Valves: What’s the Difference?, this guide explains how they work, their key advantages, and which applications each one is best suited for.

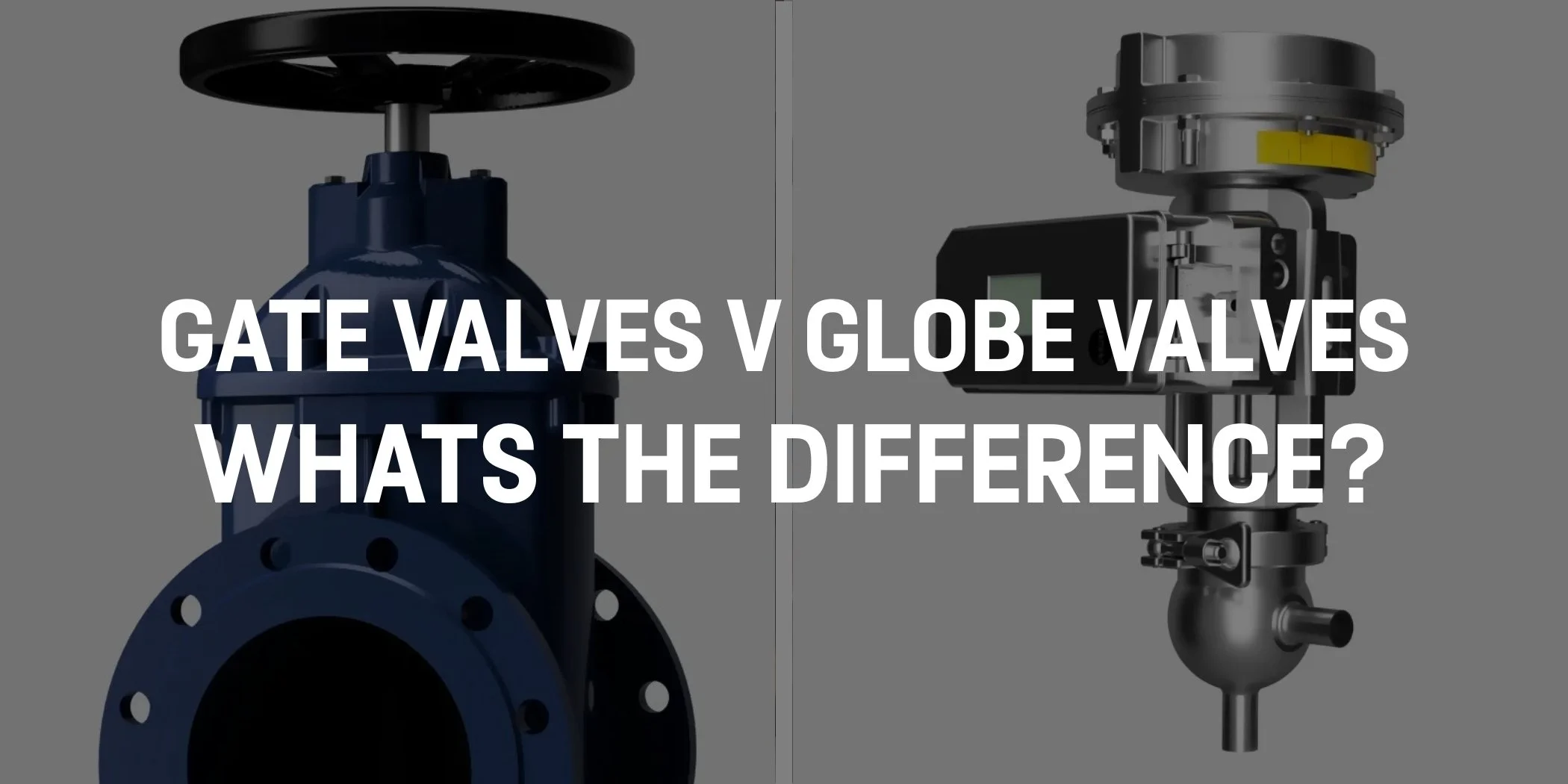

Gate Valve vs Globe Valve: What’s the Difference?

Gate valves and globe valves are often confused, but their functions are very different. If you’ve ever asked, Gate Valve vs Globe Valve: What’s the Difference?, this guide explains how each valve works, their key differences, and which applications they’re best suited for.