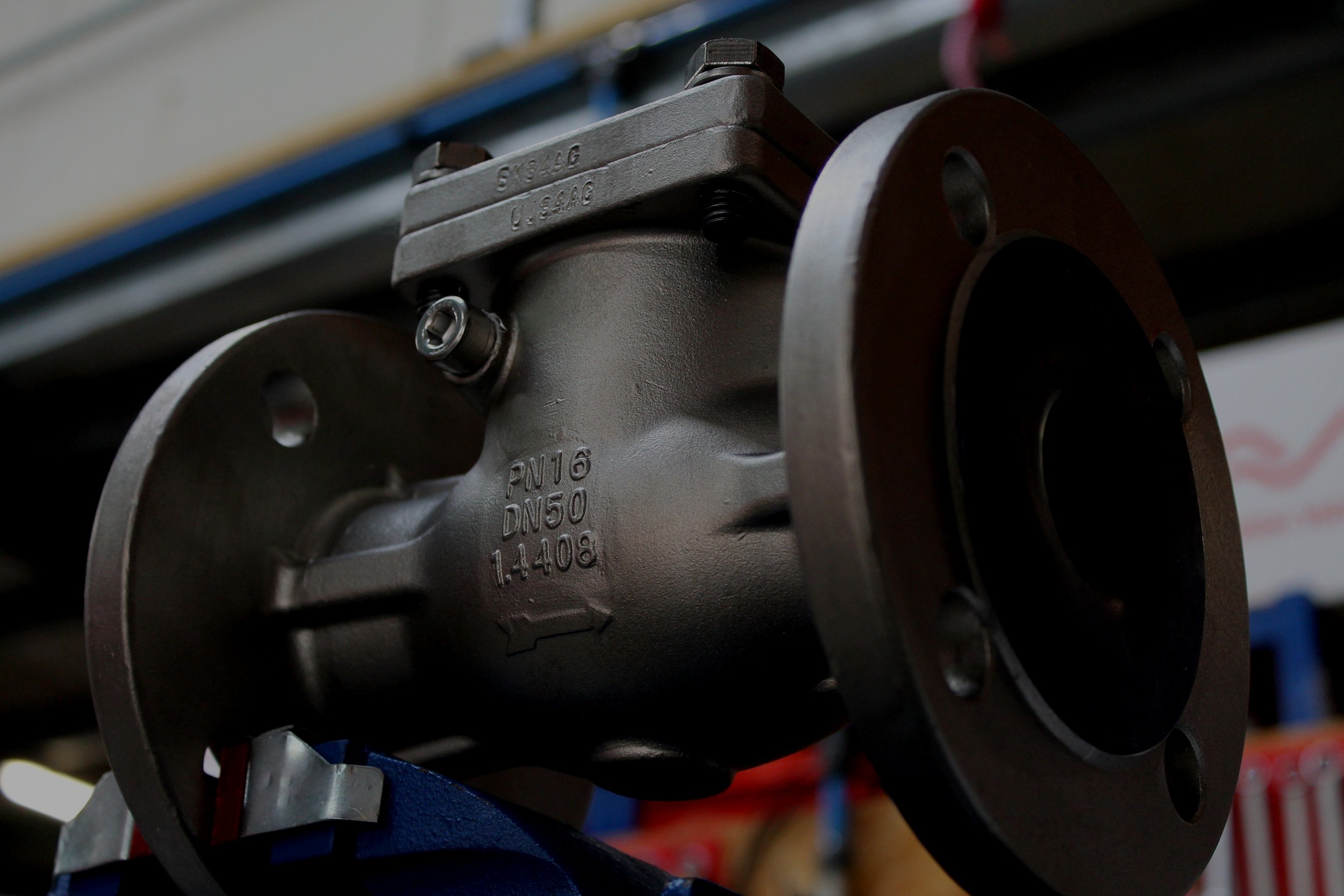

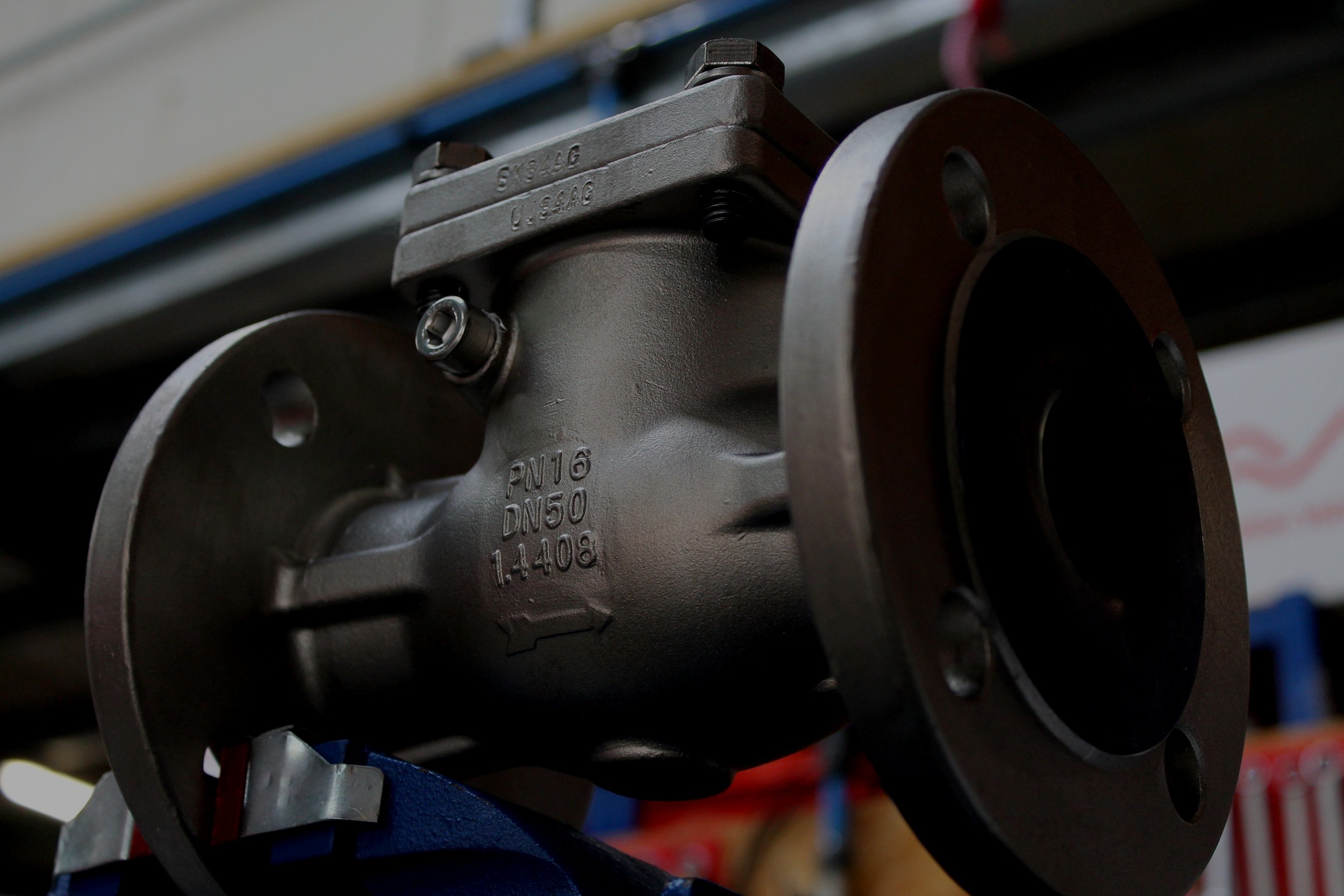

Check valves are critical for ensuring one-way flow in process systems. Over time, wear, corrosion, or debris can affect their sealing surfaces, causing backflow, system inefficiencies, or even full failure. At ValveRepair.com, we provide specialist check valve repair services designed to restore full functionality, performance, and pressure integrity—without the cost of complete replacement.

From swing and wafer-style valves to piston and dual-plate designs, we service all types of check valves with precision. Whether the issue is a sticking disc, worn seat, broken spring, or damaged hinge pin, our experienced team identifies the root cause and applies proven repair techniques. All work is carried out in-house using high-quality OEM or equivalent components, with pressure testing and certification included as standard.

CHECK VALVE REPAIR

WHY CHOOSE US FOR CHECK VALVE REPAIR?

At ValveRepair.com, we understand the vital role check valves play in maintaining safe, efficient flow systems—whether in industrial pipelines, pump discharge lines, or steam condensate networks. That’s why our check valve repair service is built around quality, speed, and precision. We go beyond simple fixes by offering full diagnostic reporting, expert reconditioning, and reliable part replacement using OEM or high-grade equivalents.

Our experienced engineers handle everything in-house, from swing and wafer check valves to more complex dual plate or spring-loaded designs. Every repaired valve undergoes rigorous pressure testing to confirm leak-tight sealing and correct non-return operation before it’s returned to service. We also offer UK-wide collection and return, fast turnaround, and emergency repair options to reduce downtime. With full certification included and decades of industry experience behind every job, ValveRepair.com is your trusted partner for dependable, cost-effective check valve repair.

HOW WE REPAIR CHECK VALVES?

Our check valve repair process is designed to fully restore functionality, eliminate backflow issues, and extend service life. It starts with a thorough inspection of all internal components, including the seat, disc, spring, hinge mechanism, and sealing surfaces. We assess for common issues such as erosion, corrosion, misalignment, or foreign material obstruction that could prevent proper closing or sealing.

Once inspected, the valve is completely disassembled. Damaged or worn components such as springs, pins, seals, or seats are either repaired, machined, or replaced with OEM or high-quality alternatives. We then carry out internal cleaning to remove scale, debris, and residue that may impact performance. All moving parts are reconditioned, ensuring the disc or plate opens and closes smoothly with no sticking or delay.

CHECK VALVE REPAIR SERVICES

Visual Inspection & Function Testing

Seat and Disc Reconditioning or Replacement

Spring, Hinge & Pin Replacement

Internal Cleaning & Surface Finishing

Seal Repacking & Refitting

Hydrostatic or Pneumatic Pressure Testing

Each valve is reassembled and tested to ensure reliable non-return functionality under your specific operating conditions.

We help you extend the lifespan of your check valves and avoid costly replacements—fast, reliable, and fully tested before dispatch.

/

We help you extend the lifespan of your check valves and avoid costly replacements—fast, reliable, and fully tested before dispatch. /

Visual Inspection & Function Testing

SERVICES INCLUDE

Every check valve repair begins with a detailed visual inspection and functional test to identify signs of wear, corrosion, blockage, or mechanical failure. We assess the condition of all internal components and confirm whether the valve is opening and closing as it should, providing a clear diagnosis before any work is carried out.

Internal Cleaning & Surface Finishing

Over time, check valves accumulate scale, debris, and corrosion that impair performance. We carry out thorough internal cleaning and surface finishing to remove contaminants and improve the movement and sealing surfaces of all critical parts.

Seat and Disc Reconditioning or Replacement

Damaged or worn seating surfaces and discs are a common cause of leakage and backflow. We restore these components through precision machining and lapping, or replace them entirely if needed, to ensure a tight, reliable seal and optimal flow direction control.

Seal Repacking & Refitting

If the check valve contains gaskets, seals, or O-rings, we repack and refit them using materials suitable for the valve’s pressure, temperature, and media. This step is essential for preventing leaks and maintaining operational safety.

Spring, Hinge & Pin Replacement

For swing and spring-loaded check valves, internal parts such as springs, hinge pins, and retainers are crucial to proper operation. We remove any broken or fatigued components and fit new ones to restore responsive movement and non-return functionality.

Hydrostatic or Pneumatic Pressure Testing

After reassembly, all repaired check valves are rigorously tested using hydrostatic or pneumatic methods. This confirms the valve holds pressure, prevents backflow, and meets operational standards. Full test certification is provided with each repair.

FAQs

What are the signs a check valve needs repair?

Symptoms include backflow, fluid hammer, noisy operation, or reduced system pressure. Sticking or failure to open/close is also common.

Can you repair all check valve types?

Yes, we repair all common types including swing, wafer, piston, and dual plate check valves, regardless of size or material.

Do you replace worn or broken internal parts?

Absolutely. We replace springs, seats, hinge pins, and any other components that are worn or damaged during the repair process.

How do you test repaired check valves?

All valves are hydrostatically or pneumatically tested to verify correct operation and sealing, and we provide full test certificates upon completion.

Do you offer collection and delivery?

Yes. We provide a UK-wide logistics service to collect and return your valves, reducing disruption to your operations.

Can you upgrade materials during repair?

Where possible, we can upgrade seats, discs, or internals to suit harsher media or higher temperatures. Let us know your requirements during booking.