YOUR VALVES SECOND LIFE STARTS HERE

VALVE REFURBISHMENT

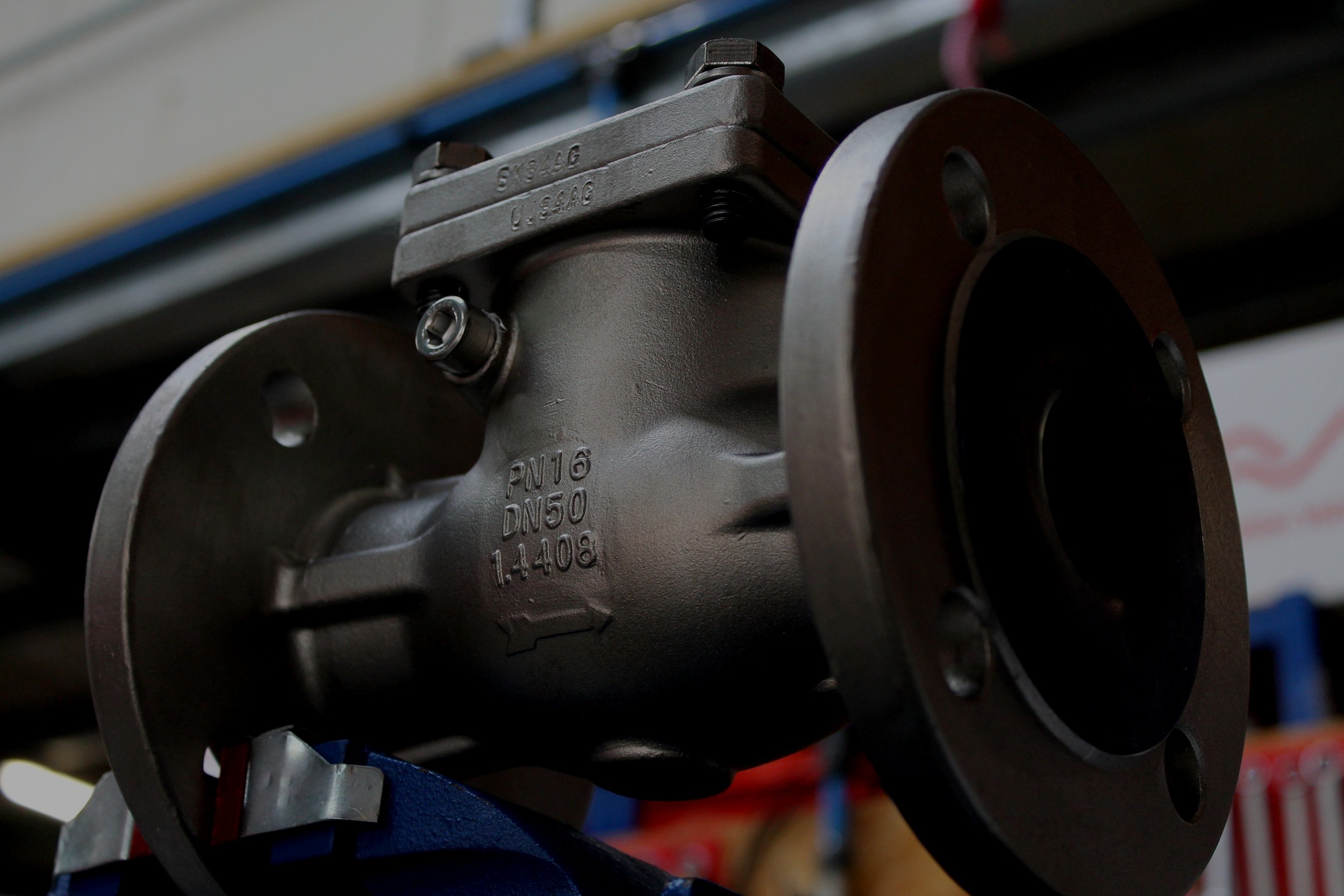

Over time, valves naturally degrade due to constant exposure to high pressures, extreme temperatures, corrosive media, and repetitive cycling. This wear and tear can lead to internal erosion, seal breakdowns, reduced flow control, and eventual failure if left unaddressed. At Valve Repair, we specialise in breathing new life into these essential components through a comprehensive refurbishment process.

Each valve is fully dismantled and inspected, allowing us to identify signs of damage, corrosion, or fatigue. We then replace or re-machine worn or damaged components, such as seats, stems, seals, and discs, using industry-approved materials. Internal parts are carefully cleaned, resealed, and recalibrated to ensure leak-tight operation and optimal performance. Once reassembled, the valve is tested under pressure to verify function and reliability — effectively restoring it to a like-new condition ready for continued service in demanding environments.

VALVE PRESSURE TESTING

Valve Pressure Testing is a crucial quality assurance process used to verify the integrity, performance, and safety of a valve before it returns to service. Over time, valves can develop internal or external issues such as seat wear, body cracks, or seal degradation — all of which can compromise their ability to maintain pressure and prevent leaks. Through rigorous pressure testing, we evaluate whether a valve can withstand its designated operating and maximum allowable pressures without leaking, deforming, or failing under stress.

At Valve Repair, we conduct both hydrostatic and pneumatic pressure testing, depending on the valve type and application. These tests simulate real-world operating conditions to expose any structural weaknesses, seal failures, or operational inconsistencies. Our pressure testing procedures follow industry standards and customer specifications, ensuring the valve is certified for safe, leak-free, and long-term use in demanding environments. Full documentation and test certificates are provided for traceability and compliance.

EMERGENCY VALVE REPAIR

When a valve failure strikes, it can bring entire systems to a standstill — and in high-pressure environments, every second counts. At Valve Repair, we offer rapid-response emergency valve repair services designed to minimise downtime and restore critical operations without delay.

Whether you're dealing with a major leak, a seized isolation valve, actuator failure, or a full mechanical breakdown, our experienced technicians are equipped to respond swiftly, diagnose the issue on-site or off-site, and begin repairs immediately.

WHAT INDUSTRIES DO WE SERVE?

With a dedicated workshop, mobile repair services, and a wide inventory of spares, Valve Repair is your trusted partner for valve performance — no matter the industry. We help clients avoid unnecessary replacement costs, extend equipment life, and maintain compliance every step of the way.

With a dedicated in-house workshop equipped for everything from full strip-downs to precision machining, we’re able to carry out detailed inspections, testing, and overhauls on a wide variety of valve types. Our technicians are highly trained and work to industry-recognised standards, ensuring each repair is performed with accuracy and care.

Wondering what industries we serve?

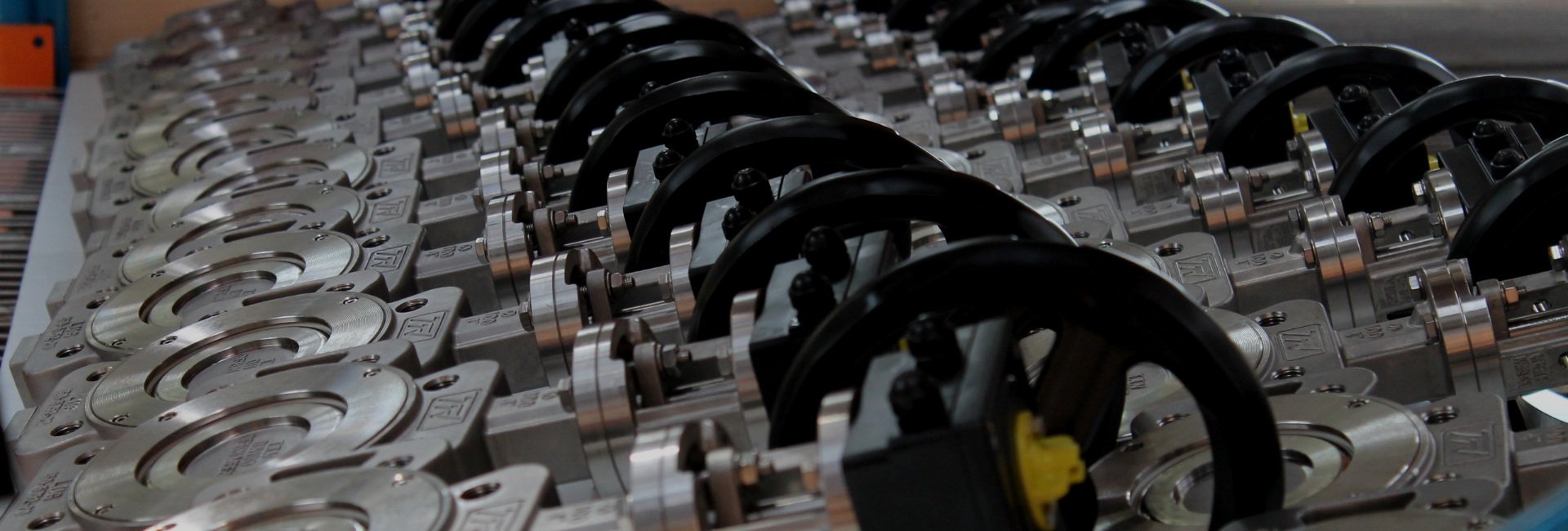

From ball valves to globe, butterfly, gate, and check valves – we repair them all.

Explore our full range of valve repair services by valve type and find the right solution for your system.

Fast turnaround, certified testing, and expert workmanship guaranteed.

Where Downtime Ends and Reliability Begins

/

Where Downtime Ends and Reliability Begins /

IN NEED OF A NEW VALVE?

CONTACT US

Whether you’re facing an urgent breakdown, planning preventative maintenance, or simply looking for expert advice — we’re here to help. Fill out the form below with a few details about your valve issue or project, and a member of our technical team will be in touch shortly.

At Valve Repair, we pride ourselves on fast response times, honest advice, and high-quality workmanship backed by over 25 years of experience. From on-site emergency callouts to complete workshop refurbishments, we work with businesses across multiple industries to restore valve performance and prevent costly downtime.

We look forward to learning more about how we can support you — and getting your operations running smoothly again.